Megha-Structure, Blog #02

Petronas Twin Tower

Tallest Twin Tower in the world

Photo by https://unsplash.com/photos/city-skyline-during-night-time-GdjZs5JZwZA.

Malaysia’s Petronus Towers are the tallest twin towers on the planet. Building these 450 m giants pushed the outer limits of construction technology. Every twist and turn in the project brought drama and near disaster. Today they stand, a symbol of Malaysian pride and modernity. All in a country that had never built a mega skyscraper before!

They were built to be the tallest buildings on Earth. A gargantuan pair of towers dominating the skyline of Malaysia’s capital, KualaLumpur. The mighty Petronus towers scale 88 stories to a breathtaking 450 m, nearly half a kilometer high. Cleaning the 16,000 windows in just one tower takes a month. Inside 10,000 people live and work. This is a city in the sky but building the towers was a construction challenge like no other. At every turn, unexpected problems threatened the project. They were building in the heart of Asia’s torrential monsoon belt. The construction site wasn’t made of bedrock, but unstable sediment. The towers were to rely not on lightweight steel, but concrete. A high-risk showcase project with a hugely ambitious schedule. So why do it?

The backstory

Humanity has always yearned to reach higher, climb further. Magnificent buildings symbolize power, success, and technical leadership. The skyscraper age dawned over a hundred years ago. Chicago and New York competed for the title of tallest building in the world. Towering giants of glass and steel, each higher than the last. We now live in the age of the mega skyscraper. New York’s tallest buildings were the twin towers of the World Trade Center, recognizable across the globe. Finished in 1977, they topped out at 417 m. But Chicago’s Sears Tower, built in 1973, held on to the record, the ultimate expression of corporate and national pride.

“The primary reason why people build tall buildings is ego.”

It had always been an American contest. Chicago had held the crown unchallenged for two decades. No one dared even try to compete. But now, a new young country joined the race. Southeast Asia entered the 1990s with the world’s fastest growing economies. Tiger nations hungry for success. Now they wanted to show the world they’d arrived. One country above all wanted to put itself on the map by breaking the US monopoly on mega buildings, Malaysia.

It’s Prime Minister, Dr. Mahati Muhammad had turned Malaysia into a regional powerhouse with a vision for the future. He was determined to win global recognition. He set a challenge that would do just that.

The Racecourse & the Petronas the oil company:

“Of the five Southeast Asian countries, Blacia was the least known. So in order to tell the world that we are here, we have arrived, uh we need something spectacular and I think a tall building provides that answer.” – Prime Minister, Dr. Mahati Muhammad

But pushing at the boundaries of the possible meant taking risks. A symbol of national pride could easily turn into the spectre of national humiliation. The year was 1991, the site of Kuala Lumpa’s racecourse was about to become the centerpiece of the new Malaysia. The brief was to create a pair of giant skyscrapers. They were to be the new home of Malaysia’s national oil company, Petronis, the biggest business in the country. They would transform the face of Kuala Lumpur. But there was a catch.

The prime minister wanted it tall, but he also wanted it to be uniquely Malaysian. And that was no easy task. Traditional Malaysian architecture was decidedly low rise.

César Pelli was already one of the world’s leading architects with nearly half a century’s experience designing skyscrapers, but he knew this one was different.

The Concept and the Form generation

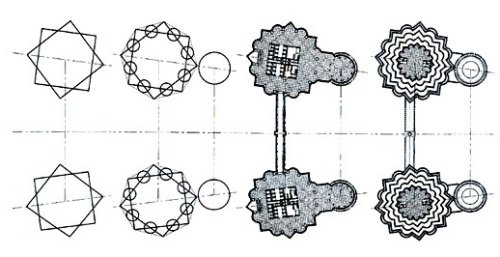

He soon discovered that when they said Malaysian, they meant Islamic. And Islamic art is utterly distinctive. Because Islamic law forbids depictions of people, it uses geometric designs like circles or plants and letters of the alphabet. He looked at every book on Islamic art, every publisher. But how to translate all that into a skyscraper?

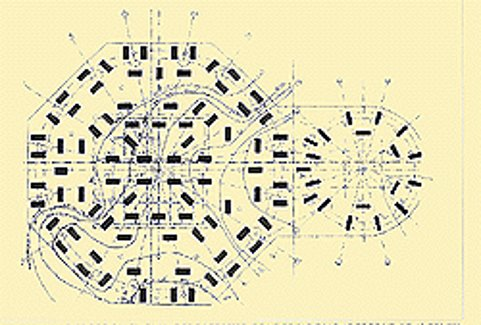

César Pelli came up with a revolutionary two tower design. He linked them with a bridge halfway up to make a symbolic gateway to the new Malaysia, something nobody had attempted before. Py flew to Malaysia to present his ideas to the key players. It was a huge gamble. They loved the concept, but the prime minister didn’t think it was Malaysian enough. César Pelli modified his design again and again, each time it was rejected. The project, it seemed, was doomed before it even reached the drawing board. Then a sudden breakthrough from a surprising source. The prime minister took matters into his own hands. He put my ideas on paper in order to give it some Islamic inputs. His idea was for a floor plan based on two interlocking squares.

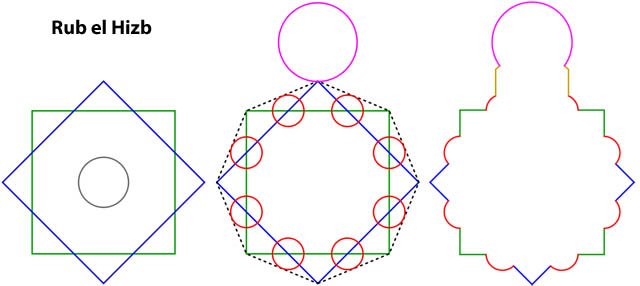

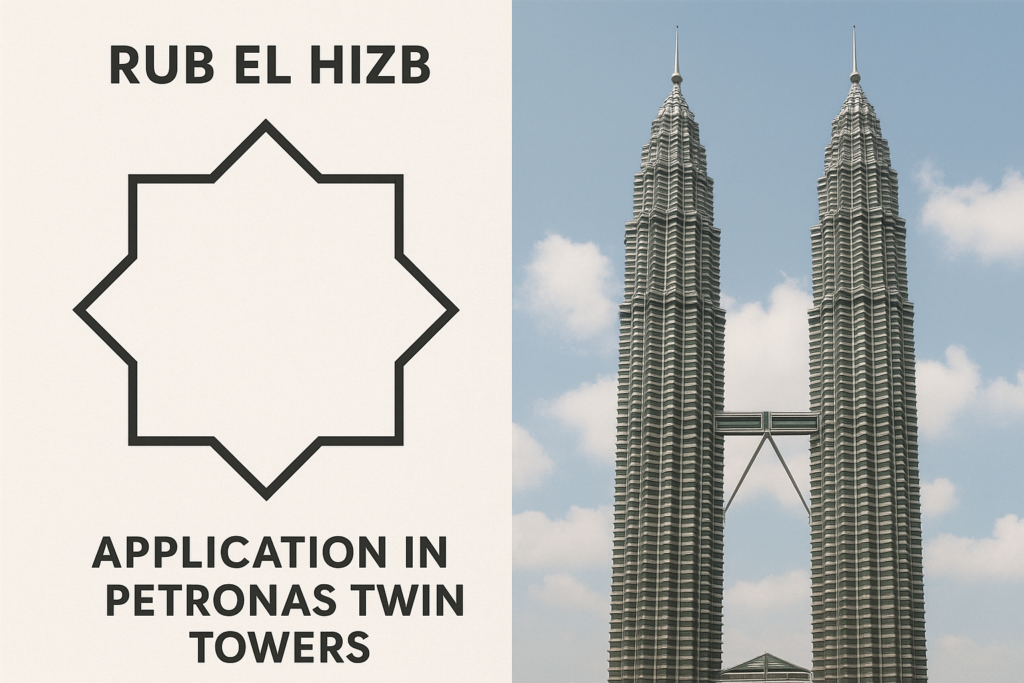

The RUB-EL-HIZB:

This Islamic art is called Rub-El-Hizb. The Rub el Hizb (۞) is an Islamic geometric symbol consisting of two overlapping squares forming an eight-pointed star. Traditionally, it is used in the Quran to mark the end of a chapter or passage, symbolizing balance, harmony, and guidance.

Application in Petronas Twin Towers:

-

The design of the Petronas Twin Towers in Kuala Lumpur, Malaysia, is heavily inspired by Islamic art and geometry.

-

The floor plan of each tower is based on a simple Rub el Hizb shape (two interlocking squares), reflecting Islamic heritage and symbolism.

-

To maximize usable office space, the architect (César Pelli) added circular sectors at each corner of the star, blending tradition with modern practicality.

This use of the Rub el Hizb embodies both spiritual meaning and structural elegance, making the towers not only architectural marvels but also cultural icons.

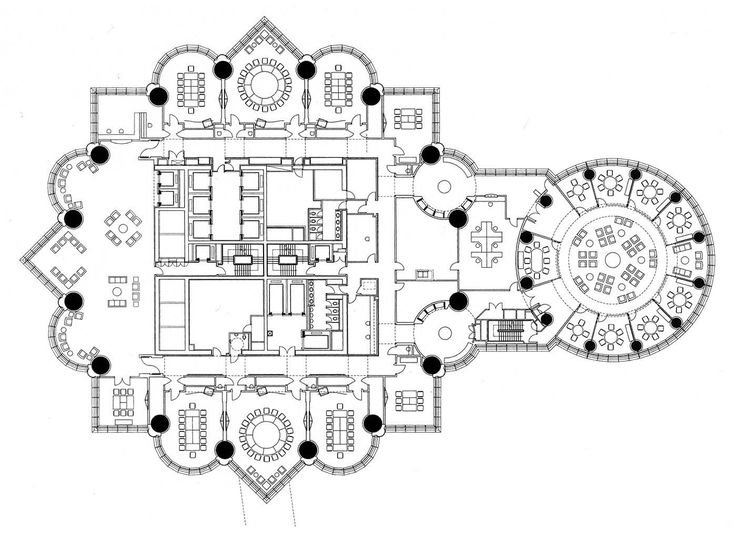

In Islamic symbolism, this represents order and harmony. At last, the prime minister was happy. But César Pelli still had a problem. The design wouldn’t supply the floor space they needed. How could he satisfy the brief and the prime minister? The Petronus towers were deadlocked at the design stage. Finally, 8 months into the grueling process, architect César Pelli produced a plan that pleased everybody. He embellished the floor plan with semic-ircular scallops, increasing space without destroying the underlying symbolism. They had their design. Now they were going to have to turn it into reality.

The Design Development & the Execution

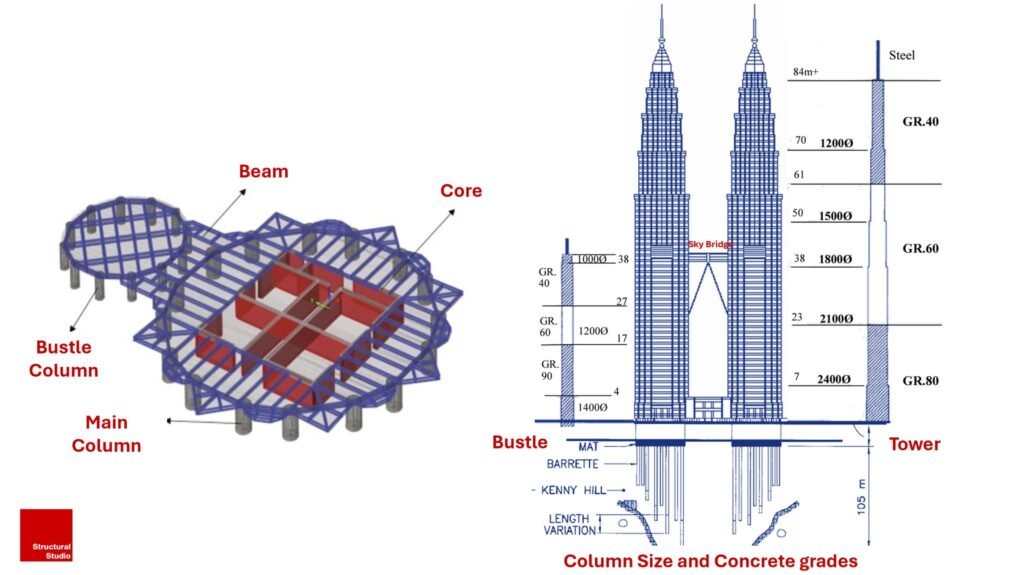

The man faced with this mammoth challenge was structural engineer Charlie Thornton. He’d been involved from the beginning, making sure Pelli’s unique ideas could actually be built. Thornton’s a skyscraper specialist. Thornton realized 15 m higher would overtake the Sears Tower, the world’s tallest building. The prime minister jumped at the chance to take the world record. Petronas was now to be 450 m high, the tallest building on Earth. It was a colossal challenge. The schedule was desperately tight. Normally, this would have been an 8-year build. The Malaysian budget only allowed for six. to focus their minds. Every day past the deadline would cost the builders more than $700,000, $5 million a week!

The two Company:

Then the Malaysians did something very unusual. The contracts for the two towers went to two different construction companies. The prime minister believed competition would keep things on track. The pressure was immense. To stay on schedule, construction would have to run uninterrupted 24 hours a day, 7 days a week. An exhausting workload. The Malaysians wanted the best men to lead their two teams. They wanted to learn from the experts. So, they decided to play safe for the first and last time in this roller coaster project. They went to the place with a skyscraper track record a century long, New York City.

Tower One -Japan’s Hazama Corp.

Tower Two -Korea’s Samsung Engineering and Construction

Foreman Bob Pratt was in charge of Tower 1. Pratt’s rival was Tower 2 foreman John Dunford. He was in France when he got the call. The two men, complete with families, arrived in Malaysia, their home for the next 6 years. The budget clock was already counting down the time they had to finish the task.

The Challenges:

1993, March Start of the excavation

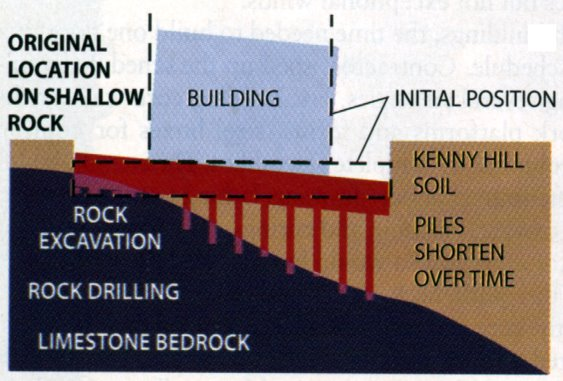

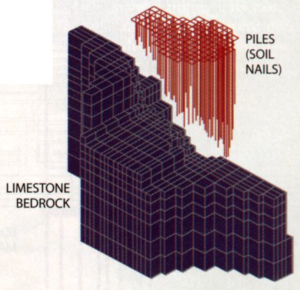

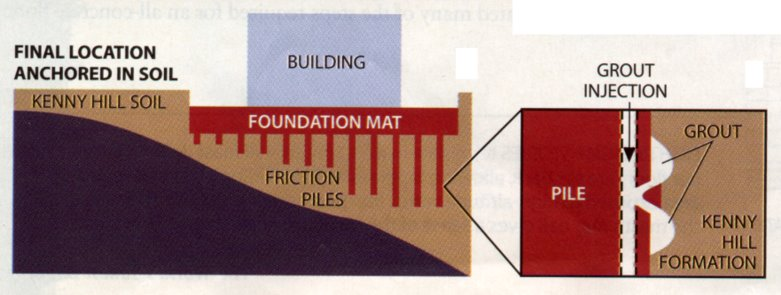

They found they couldn’t even start. They hit a major obstacle before the first bucket of concrete was poured. There was something wrong with the ground.The engineers discovered there’d never been a proper survey of the site. They needed a clear picture of the ground beneath them before any work could begin. The whole site came to a standstill. Every wasted day costs hundreds of thousands of dollars. Geologists began boring hundreds of drill holes, bringing up thousands of samples. They were looking for bedrock, something solid to support the massive towers. The survey results were disastrous. At one side of the site, there was solid limestone, but the rest of the construction area was much softer, brittle rock. It would crumble under the immense weight of two 88story skyscrapers. If they built here, the soil would settle unevenly on one side. The towers would sink or even collapse. The team could end up with the leaning towers of Malaysia. The whole project was in jeopardy. Time was ticking away as they searched for a solution. Charlie Thornton’s idea was nothing if not daring. He proposed moving the entire building 60 m onto the softer ground. It seemed like a mad idea, but there was clear thinking behind it. They planned to drive a series of enormous piles 120 m down through the soil to the hard strata beneath. Then they could make their own bedrock on top. The buildings were going to sit on a vast concrete raft. In effect, they were going to nail the towers to the ground with the world’s deepest foundations. It was early 1993. Construction finally got started.

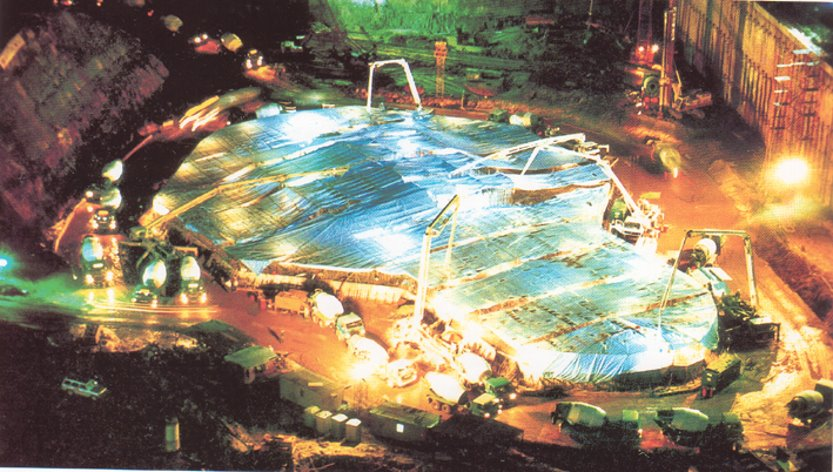

Building the foundation slab was going to be a huge job in itself. If the concrete dried unevenly, the whole raft would crack. It could seriously weaken its ability to support the giant building above. So, they were going to have to pour it all in one go. That meant pouring concrete for 52 hours without a break, a truckload every 2 and 1/2 minutes. It was going to be the biggest concrete slab in Malaysian history. The logistics were mindbending. Charlie Chilea was in charge. For the first 5 hours, everything went well. Then the rains hit Kuala Lumpur. The team had to think fast. They expected rain, but nothing like this. It was torrential, heavy tropical rain. The concrete could get too wet. It looked like they were going to fall at the first hurdle. The tiniest glitch at ground level would translate into a giant headache 450 m up. Unless they could do something fast, the foundations would be ruined. The team came up with a dramatic solution. They covered the entire site in canvas, the equivalent of 56 circus tents. Thanks to the biggest umbrella in the world, the foundations were finally laid successfully. No one had ever poured this much concrete at the same time before. It was only the first world record broken by the Petronas Towers. 1994 dawned and at last the two tower teams could move in. The race to the top was on. It was a fight from the start.

The race had began:

Bob Pratt in Tower 1 got a head start of a month. It looked like John Dunford’s chances of winning the tallest building prize had already been snatched from his grasp. He took it coolly. The builders on both towers ran into trouble right from the start. They had serious teething problems. Nothing went right. The schedule said each of the 88 floors had to be built in only 4 days. Right now, it was taking them eight. The sense of rivalry was mounting. That’s probably the first time there was ever a dialogue of you lost time against the other tower. The difference was clear. Bob Pratt’s Tower 1 was winning over John Dunford’s Tower 2. Speed was vital if the builders were to meet their deadline, but the smallest error could weaken the building’s structure and wreck the whole project.

The team were forced to use a new construction method, so the risk of mistakes was even higher. Nobody had ever tried it on a mega skyscraper before. A normal skyscraper hangs off a steel frame built of girders that supports the weight of the building. Steel made the first skyscrapers possible. It’s immensely strong, but also has a slight flex, something tall buildings need. But Malaysia didn’t have a big enough steel industry, and importing it would blow the budget to pieces. What Malaysia did have was concrete, vast amounts of it. It was the only way Petronis could be built. Not only was this the tallest building on Earth, they’d be using a material never tried out on this scale before, an untested technology. Instead of a steel frame to support the weight of the building, the Petronas towers would use a ring of 16 concrete pillars linked by beams. Between them, they would have to support 270,000 tons, 7 12 times the weight of the Titanic. No one had ever done this with concrete before. Malaysia’s previous tallest building was just 250 m high. The Petronas towers were going to be nearly twice that. Conventional concrete would disintegrate under the load. The Petronis engineers needed a new formula. Concrete that could do the job of steel. It didn’t just have to be strong. For an ultra tall building, there had to be a degree of flexibility. Chicago is the home of the skyscraper. Close to the city is CTL, one of the world’s largest concrete testing laboratories. With concrete, tiny changes in the recipe can make a huge difference to how it performs under pressure. And the Petronis towers would certainly push it to breaking point, if not beyond. As if that wasn’t enough, they could only use raw materials locally to hand in Malaysia. The mix was essential. Just a pinch too much of one material could be disastrous. In the lab, scientists worked their magic with the most basic ingredients: gravel, water, cement. They started with the recipe they knew using Malaysian materials in the same quantities they used in the states. For the test block, it was the moment of truth. The concrete for Petronis had to withstand 20,000 lb a square in the 600 mark on this dial. This small column of concrete needed to carry the equivalent of 20 trucks. The crushing weight was immense. 200 on the dial wouldn’t even be strong enough for a 20story building. 350 could support half the Petronis towers. It wasn’t good enough. It was back to the drawing board for the concrete wizards. They had to redesign the mix from scratch. They were making progress, but it wasn’t strong enough to match the demands of the Petronis design. The entire project depended on getting this right. They tried high tech additives such as silica left over from computer manufacturers which reduced air bubbles in the concrete making it stronger. It was their last hope.

Finally success! But is it though:

The team were delighted. They had their super strong material, and they needed it. A concrete patronus tower was going to be twice as heavy as a steel one. With the concrete problem solved, the teams threw themselves into the race against time. Constructing each floor was a logistical nightmare. Up to 2,000 workers, tons of concrete and heavy equipment, all moving in perfect harmony. It was a complex process. Build the support pillars, lay the floor, move on up to the next level, and repeat the process all over again. As the floors rose, the outside of the building was laboriously slotted into position. An enormous 88tory jigsaw puzzle. The complexity was immense. But things seemed to be going well. Then a batch of the super strong concrete went for routine testing and it failed. Concrete being delivered to the building wasn’t strong enough. Somebody hadn’t stuck to the recipe. So the vital question, had any of the dud batch already been built into the towers? Work came to a dead halt. If they went ahead with the wrong concrete, the results could be disastrous.

Kish Krishna Swami had the tough job of making sure the concrete lived up to its exacting specs. If they had to rip the towers apart, it could mean financial meltdown. Further investigations were slightly more encouraging. The bad concrete had only been laid on one floor. Kish Krishna Swami ordered the contractors to rip it out and start again. It had been a narrow escape. If the faulty batch of concrete hadn’t been discovered, the results would have been unimaginable. The testing facilities were upgraded. Three concrete plants right on site meant a problem with one wouldn’t hold up the whole operation. Every batch would now be tested to the limit before being poured into the towers. Precious time had been lost. They were taking the towers apart before they’d even built them. For chief engineer Charlie Thornton, it was embarrassing and expensive. More important for the two construction teams, they were struggling to stay on schedule. And if they didn’t want to face hefty penalties, they were going to have to make up time and fast. As the demanding schedule slipped away from them, the two teams were beginning to feel the strain. It wasn’t just faulty concrete that had caused delay. Now, the floor laying process was creating a bottleneck. Laying floors was the most time and labor-intensive part of the construction process. In a normal Malaysian building, it took up to 10 days per story. And because the floor helped stabilize the whole building, they couldn’t build the next floor on top until it was ready. They pushed the cycle time down to 4 days, but that didn’t make things any easier. They still had to go over to 24-hour working, 7 days a week.

The Site that never slept:

1995, May Pre-assembled Skybridge arrives from South Korea.

Long hours took their toll. Construction was at last back on track. Bob Pratt’s tower 1 stood at 64 floors. John Dunford’s tower 2 still lagged behind at 60. The race was on. They were now more than 300 m up, towering above every other building in the city. Tiredness and stress led to mistakes. The Petronis Tower site was one of the safest in the world. But working almost a third of a kilometer above the Earth, the slightest error could be fatal. Even with the best safety precautions, it was an awesome height. Slender scaffolding, hard hats, and safety ropes were all that stood between workers and the immense drop. Even the most experienced could find themselves paralyzed by fear. Mid 1995, 18 months to go. As the towers took shape, they began to dominate the Kuala Lumpur skyline. Beneath the Skywalkers building the exterior, attention now turned to the inside of the towers. It wasn’t enough to build the walls. These had to be living, breathing buildings. The complex was to consist of offices, a shopping center, and an 800 seat auditorium with 10,000 people using the towers every day. The biggest challenge was getting them where they wanted to go. Elevators take up a lot of space, something the slender Petronis Towers didn’t have to spare. The core of a building like the Sears Tower would take up a huge proportion of the floor space of Petronis. They needed a radical new solution. To solve the problem, they brought in Otus, the company who literally invented the elevator.

Otus, The Company that invented elevator:

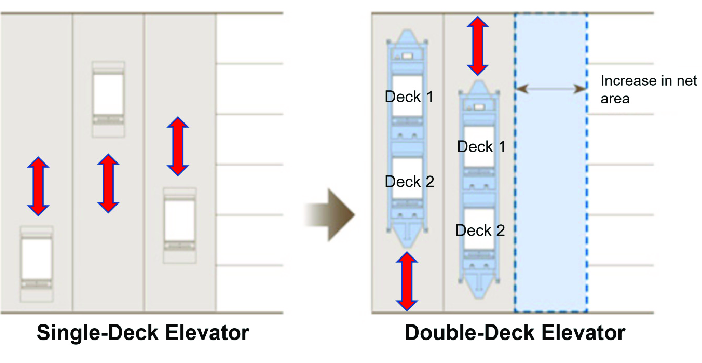

They went for high-speed elevator cars, but they couldn’t make them run as fast as they’d like to. People in Asia don’t like to go as quickly as Americans. They still needed four times the space they had available. It was a real headache for the engineers. Getting people around looked like being the Achilles heel of the Petronis towers. Then they came up with an ingeniously simple answer. They used what Petronas had plenty of height. They stacked two elevators on top of each other. Double-decker cars. When people enter the towers, they choose whether they’re going to go to an odd or even floor. For odd floors, they stay at lobby level and use the bottom deck of the car. For even floors, they go up a floor and use the upper deck. 58 double elevators can service both towers. Then they doubled up again. The system uses two double elevators in every shaft. An express elevator goes halfway up to what’s called the sky lobby. And then passengers change to a local elevator. Never more than 70 seconds to reach any floor. This ingenious solution meant the elevator core would be half the size.

https://www.researchgate.net/figure/Double-deck-elevators-save-on-the-number-of-shafts-needed-to-serve-a-building-Source_fig4_369501735

Disaster struck again:

1995, August Skybridge is lifted into place.

They hit the final months of 1995, year five of the six-year schedule. Outside in Tower 1, Bob Pratt was still two floors ahead of John Dunford in Tower 2. 72 against 70. He’d led the race from the start. They were finally on schedule. They thought the end was in sight when disaster struck. With a mega build on this scale, progress had to be monitored in depth. Bob Pratt was about to get some bad news. Precisely 25 mm of Bad News. The worst had happened. Tower 1 wasn’t straight. It was about the width of a thumb off vertically. Even worse, news leaked out, and this was a very public project. It wasn’t enough to jeopardize the building’s structural integrity, but the Petronis Towers were a prestige venture, and it was an embarrassment, something they could really do without. If Bob Pratt’s team carried on the way it was going, the situation would get worse and worse. He was at his wit’s end. Even the weather seemed to be conspiring against him. The Tower 1 team had to resist the urge to panic. Carefully, they started to correct the problem, building the tower back towards vertical. The next 16 floors would slant two barely visible millime back into line. Plans had to be recalculated. It was a setback Bob Pratt could ill afford. John Dunford in tower 2 was right on his heels. The race was really hotting up as they moved into the final straight. The two towers now stood at over 80 floors. But the safety of high-rise buildings was about to become the next nightmare for both teams. The Petronis Towers are now the tallest buildings in Asia, even unfinished, a towering symbol of Malaysia’s national pride. A horrific incident 15,000 km away made their very height a source of vulnerability.

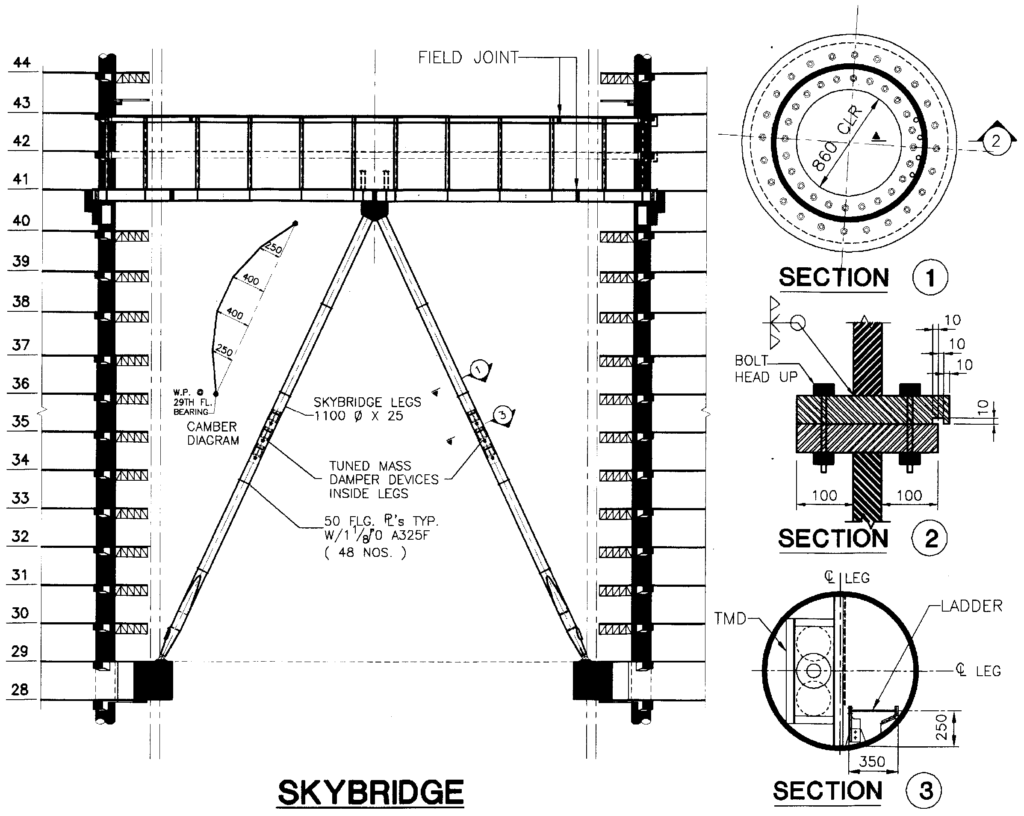

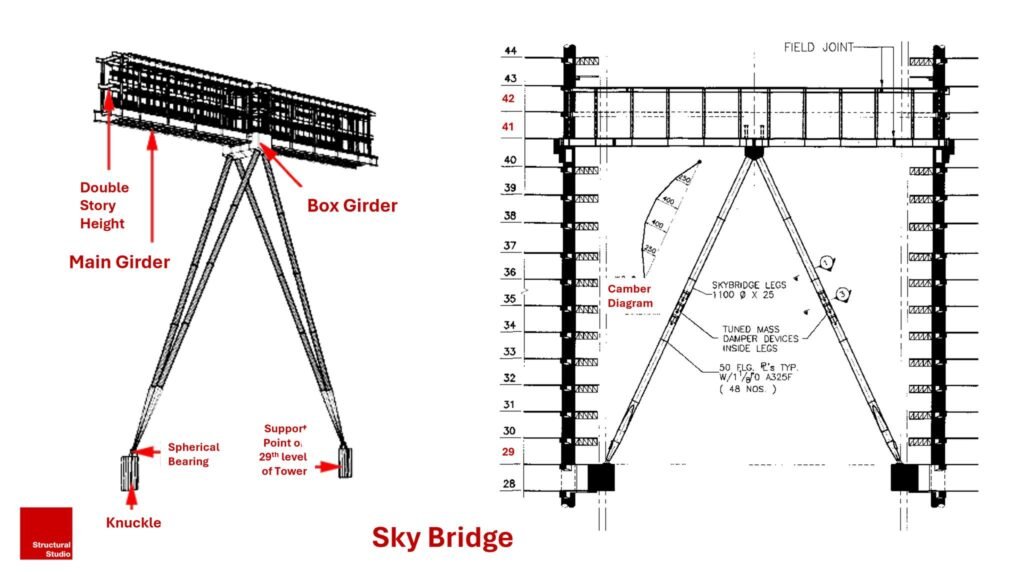

The Most Iconic Double decker Bridge

1995, August Skybridge is lifted into place

Fire is the nightmare that haunts all designers of tall buildings. They had to have a way of getting people out and fast. If they got it wrong, it could be a disaster. 2003, downtown Chicago. The workers at Cook County Office Building knew not to use the elevators during a fire. It didn’t help them. The escape staircase itself filled with smoke. With no alternative exit route, six people didn’t make it out alive. The patronus team had to make sure a fire couldn’t trap workers in the upper floors where emergency ladders couldn’t reach them. But they had two towers at their disposal. If they could make the two buildings function as one, then each could be the other’s escape route. But right now there was a 60 m gap between the two towers and safety. The answer was architect Pelly’s most startling innovation of all. The skybridge was the most brilliant part of the whole design. The bridge meant in an emergency people from one tower could escape down the other. It halved the need for staircases. In the past, links like this had only ever been built near ground level. It was a daring leap of imagination. The skybridge made the towers instantly recognizable across the globe, the finishing touch that created architect Caesar Pelly’s gateway to the future. It was also a nightmare for the engineers. All tall buildings sway in the wind. If the towers stood independently, that wouldn’t matter. But with a bridge fixed between them, their movement could cause catastrophic strains. The team needed the towers to sway as little as possible. It was up to Charlie Thornton. Tests in the wind tunnel showed Petronis was going to be one of the most stable tall buildings ever built. Using tons of concrete had caused huge weight headaches during design and construction, but that same weight significantly reduced sway. Even so, the towers would still move and there was nothing more they could do about it. They came up with an ingenious solution. Enormous bearings would allow the bridge to move freely, but they would also keep it exactly between the towers. John Dunford, leading the tower 2 team, got the bridge gig. It was up to him to lift the colossal structure into place. Bob Pratt in tower 1 was pleased to be a spectator. They were relying on the sky bridge to make the huge building safe. If they couldn’t haul it into place, the towers would be a potential death trap for thousands. The team couldn’t afford for the lift to go wrong. The prime minister himself was watching. And thanks to the international media, so was the rest of the world. Could they lift the now famous skybridge? If anything went wrong, it would be a very public spectacle. John Dunford decided the sky bridge should be assembled on the ground and lifted into place in one gigantic piece. It was a logistical nightmare. The closest anyone had ever come before was in bridge construction. So, the Tower 2 team borrowed bridge building techniques. They were going to lift the skybridge using 16 hydraulic jacks. It’s 8:30 in the morning. They’ve allowed themselves 20 hours to get up 170 m. It was a painfully slow process and one fraught with danger. After each lift, just 30 cm at a time, the cables had to be tied off and the jacks reset. The team were delighted with their progress, even if the reporters weren’t. But then the unimaginable happened.

In the intense tropical climate of Kuala Lumpur, lightning was a frequent visitor. As the site plunged into darkness, the enormous skybridge was left dangling in midair. The electricians worked frantically to get the system up and running. The hours ticked away. Finally, they were ready. It was well into the second day. Just as they thought they were going to make it, the lightning struck again. The bridge was still tantalizingly 20 ft short of its destination. They were ready to go again. But the weather wasn’t finished with the Patronus Skybridge. Three times the cranes were struck as they fought to lift the bridge into place. Three times the control circuits burned out. A nerve-wracking 20 hours turned into a nerve shredding 36 hours. Success was so near yet so far. At last, the weather gave them a much needed break. Finally, the bridge reached the top of its 170 m hoist. The moment of truth. Had they got their calculations right? Would the bridge fit onto its massive legs? At last, something went right. The bridge was a perfect fit. The relief was overwhelming. John Dunford and his team raced across the bridge. The last 3 m were just open steel with no railings. Then a 1 m gap across a 500 ft drop. The very first people to cross between the two towers. Petronis could now be the safest tall buildings in the world. The awe inspiring skybridge meant each tower had an escape route through the other. The gruelling race between the two Patronis towers to be the tallest building on Earth reached its final stage. It was December 1995 with only weeks left until completion. The contest went down to the wire. From the start, John Dunford had been behind in Tower 2. But now it was time for Bob Pratt to find out what it felt like to come second.

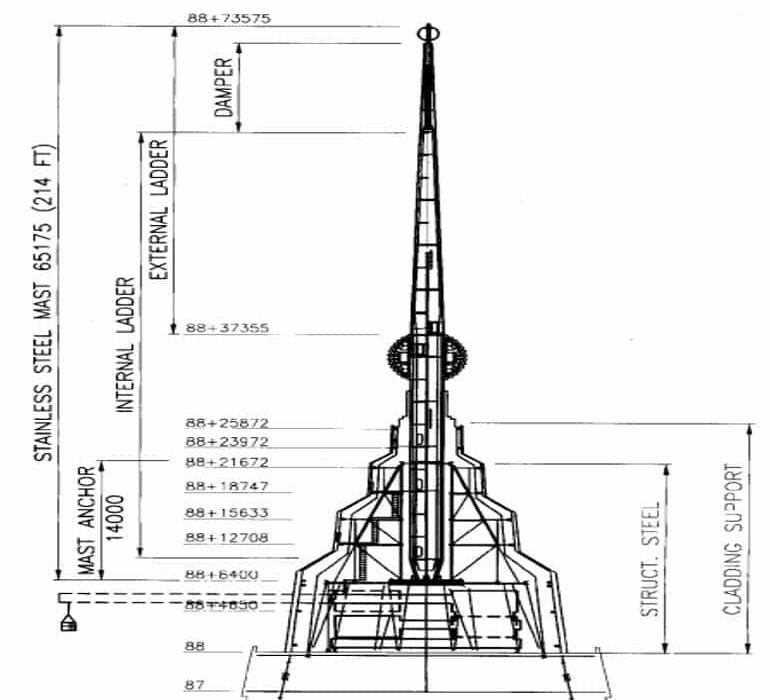

The pinnacles:

1996, March Installation of pinnacles for both towers.

Completing the 88th floor wasn’t the end of the story. The Petronis Towers still weren’t as high as Chicago’s Sears Tower, the tallest building in the world. There was one finishing touch before they took the crown. The pinnacles.

The pinnacles were why Petronis would win the world’s tallest title. The official calculation includes the height of Spires. The antennas that top the Sears tower didn’t count. The pinnacles were enormous structures in themselves. 60 m steel columns as high as another 15 stories gently tapering to a ball on the top. They were manufactured offsite and out of the country. One came from Korea, the other from Japan. The Japanese pinnacle for Bob Pratt’s Tower 1 fell behind schedule. They lost crucial days, but it didn’t seem to matter because the Malaysians had stopped the race. To create the maximum public impact, the plan was for the two pinnacles to go up together. But things didn’t go according to plan. Determined to be first, John Dunford didn’t follow orders. Tower 2 did something sneaky. Bob Pratt in tower 1 knew nothing of what was about to happen. John Dunford had a secret plan to reach the top first. His team constructed the entire pinnacle inside the tower, hidden from view. No one knew what they were going to do until it was too late to stop them. Among his team, the atmosphere was electrifying. Under cover of darkness. The lift went without a hitch. Tower 2 was the tallest building on Earth. It was a clear victory for Tower 2. Tower 1 celebrated its own exterior completion a week later. The title of the tallest buildings in the world now belongs to Kuala Lumpur. They’d done it within the six-year deadline with days to spare. It was an awesome achievement. The towers were an immediate hit. Their unique inspiring silhouette has become a symbol of the country and the whole region.

The End

1996, April Petronas Towers officially declared the world’s tallest building.

“This was my hope to come close to what the Eiffel Tower did for Paris for these towers to do for Kuala Lumpur and Malaysia.”

Exactly as the prime minister dreamt, they put Malaysia unforgettably on the map.

“Whenever people see the building, they will think of Malaysia”

the Petronis Towers as having overcome nature’s most ferocious elements and a catalog of monumental challenges. Any of them could have doomed the project. And for the people who worked on it, countless tales of rivalry, conflict, bravery, and unrelenting effort. The men and women who helped build them will never forget what they achieved here. The fears haven’t gone away. Even as new buildings now challenge for Petronis’ title, the dangers for super tall structures are brought home more sharply with every passing day. The events of September the 11th called into question the safety of this kind of landmark building. They now seem as vulnerable as they are prestigious. But the Petronis Tower’s future as a global icon is guaranteed. These are buildings unlike any other inside as well as out. The risks and six years of struggle have paid off. The Petronis Towers have made it a unique and glorious mega structure.

Photo by Nazarizal Mohammad on Unsplash